Overseas sale:Annie Yi

Mobile:0086 18998935574

E-mail:sales7@szjlgw.com

WhatApp: 0086 18998935574

Tel:0755-33160538

Fax:0755-29644707

Add:Building 1st,.Quanyuanfa Industrial Park,Zhucun,Guanlan Street,Bao'an District, Shenzhen

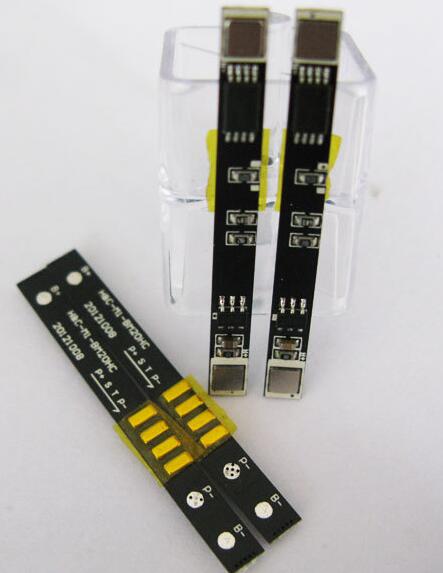

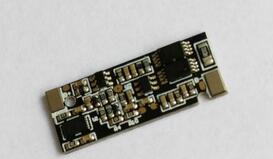

Lithium battery protection board is mainly composed of protection IC (overvoltage protection) and MOS tube (over-current protection), is used to protect the lithium battery cell safety devices. Lithium batteries with large discharge current, low internal resistance, long life, no memory effect has been widely used. Today, the creation of people and everyone to learn lithium battery protection board work steps.

First, the voltage protection capacity

Overcharge protection: The protective plate must have the ability to prevent the battery voltage from exceeding the preset value. Overvoltage protection: The protective plate must have the ability to prevent the core voltage from falling at the preset value.

Second, the current capacity (overcurrent protection current, short circuit protection)

Protection board as a lithium battery safety protection device, both in the normal working current range of the device, can work reliably, but also when the battery is accidentally short circuit or over current can quickly move, so that the batteries are protected.

Third, the on-resistance:

Definition: When the charge current is 500mA, the MOS tube on-resistance. Due to the higher frequency of communication equipment, data transmission requires a low bit error rate, the rise and fall of the pulse string steep, so the battery current output capacity and voltage stability requirements, so the protection board MOS switch switch When the resistance is small, a single cell protection board is usually<70mΩ, such as too large will lead to communication equipment is not working properly, such as the phone suddenly disconnected during the call, the phone does not pass, noise and so on.

Fourth, the consumption of current

Definition: IC operating voltage of 3.6V, no-load state, the working current flowing through the protection IC, the general minimum. Protection board consumes a direct impact on the battery standby time, usually provides protection board consumes less than current 10 microamps.

Fifth, mechanical properties, temperature adaptability, anti-static capacity

Protection board must be able to pass the national standard of the vibration, impact test; protection board in the - 40 to 85 degrees can work safely, can withstand ± 15KV non-contact ESD electrostatic test.